Marine Construction Materials: Coastal Essentials

Key Takeaways

- Marine construction materials must withstand harsh saltwater environments

- Common materials include treated wood, concrete, steel, and composites

- Each material has unique properties suited for different marine applications

- Local Charleston regulations impact material choices for coastal projects

- Proper selection and maintenance of materials ensure longevity of marine structures

Marine construction materials are the building blocks of coastal infrastructure, designed to withstand the harsh conditions of saltwater environments. These specialized components are crucial for creating durable docks, piers, seawalls, and other waterfront structures in Charleston, South Carolina. Let's look at the essential materials used in marine construction and their specific applications in the Lowcountry.

The Backbone of Marine Structures: Treated Wood

Treated wood remains a popular choice for marine construction in Charleston due to its affordability and versatility. The most common type used is pressure-treated Southern Yellow Pine, which is infused with preservatives to resist decay and marine borers.

Benefits of treated wood in marine environments

Treated wood offers several advantages for coastal projects:

- A natural aesthetic that blends with the Lowcountry landscape

- Easy to work with using standard carpentry tools

- Cost-effective compared to other materials

- Can be easily repaired or replaced in sections

Limitations of wood in saltwater

Despite its benefits, wood has some drawbacks in marine settings:

- Requires regular maintenance and occasional replacement

- Can warp, crack, or splinter over time

- May leach chemicals into the water (though modern treatments are more eco-friendly)

Concrete: Strength and Durability for Marine Applications

Concrete is another widely used material in Charleston's marine construction industry. Its strength and durability make it ideal for foundations, pilings, and seawalls.

Advantages of concrete in coastal projects

Concrete offers several benefits for marine structures:

- Exceptional durability and longevity

- Resistance to saltwater corrosion

- Ability to withstand heavy loads and wave action

- Low maintenance requirements

Challenges with concrete in marine settings

While concrete is robust, it's not without its challenges:

- Can be prone to cracking in freeze-thaw cycles (though less common in Charleston)

- May be susceptible to chemical attack from seawater

- Higher initial cost compared to wood

- Difficult to modify or repair once installed

Steel: Versatility and Strength in Marine Construction

Steel is often used in Charleston's marine projects for its strength and versatility. It's commonly found in pilings, sheet piling for seawalls and structural components of large docks and piers.

Benefits of steel in waterfront structures

Steel offers several advantages in marine construction:

- High strength-to-weight ratio

- Ability to be driven deep into the seabed for stability

- Can be coated or galvanized for corrosion resistance

- Recyclable at the end of its lifespan

Drawbacks of steel in saltwater environments

Steel does have some limitations in marine settings:

- Susceptible to corrosion if not properly protected

- Can be noisy during installation (a concern in residential areas)

- May require specialized equipment for installation

- Higher cost than some other materials

Composite Materials: The Future of Marine Construction

Composite materials, such as fiber-reinforced polymers (FRP), are gaining popularity in Charleston's marine construction industry. These innovative materials offer a blend of durability and low maintenance.

Advantages of composites in coastal projects

Composite materials provide several benefits:

- Exceptional resistance to corrosion and decay

- Lightweight yet strong

- Low maintenance requirements

- Long lifespan, often exceeding traditional materials

Limitations of composites in marine applications

Despite their advantages, composites have some drawbacks:

- Higher initial cost compared to traditional materials

- Limited load-bearing capacity compared to steel or concrete

- May require specialized skills and tools for installation

- Relatively new technology with less long-term performance data

Specialized Marine Fasteners and Hardware

The success of any marine construction project in Charleston depends not just on the primary materials but also on the fasteners and hardware used to hold everything together.

Importance of corrosion-resistant fasteners

In the salty environment of the Lowcountry, using the right fasteners is crucial:

- Stainless steel screws and bolts resist corrosion

- Hot-dip galvanized nails and brackets provide additional protection

- Specialized marine-grade hardware ensures the longevity of connections

Challenges with marine fasteners

Even with corrosion-resistant materials, fasteners can face issues:

- May still corrode over time, especially in areas of high-stress

- Can be more expensive than standard hardware

- May require regular inspection and occasional replacement

Environmental Considerations for Marine Materials

When choosing materials for marine construction in Charleston, it's essential to consider the environmental impact.

Eco-friendly options for coastal projects

Several environmentally friendly materials are available:

- Recycled plastic lumber for decking and fencing

- Concrete mixtures incorporating recycled materials

- Non-toxic wood treatments that minimize chemical leaching

Balancing durability and environmental impact

Finding the right balance is key:

- Longer-lasting materials may have a higher initial environmental cost but require less frequent replacement

- Some eco-friendly materials may not perform as well in harsh marine conditions

- Local regulations may restrict the use of certain materials to protect marine ecosystems

Material Selection Based on Project Type

Different marine structures in Charleston require different materials based on their specific needs and environmental conditions.

Docks and piers: Combining materials for optimal performance

Docks and piers often use a combination of materials:

- Treated wood or composite decking for walking surfaces

- Concrete or steel pilings for structural support

- Stainless steel or aluminum railings for safety and durability

Seawalls and bulkheads: Choosing materials for wave resistance

Seawalls require materials that can withstand constant wave action:

- Concrete or steel sheet piling for primary structure

- Riprap or concrete blocks for additional protection

- Geotextile fabrics to prevent soil erosion behind the wall

Boat lifts and floating docks: Materials for buoyancy and stability

These structures have unique material requirements:

- Aluminum or galvanized steel for lift structures

- High-density polyethylene (HDPE) or concrete for floating dock pontoons

- Composite or treated wood decking for walking surfaces

Local Regulations Impacting Material Choices

Charleston's coastal location means that marine construction is subject to specific regulations that can affect material selection.

South Carolina DHEC requirements

The South Carolina Department of Health and Environmental Control (DHEC) has guidelines for marine construction materials:

- Restrictions on certain wood treatments to protect water quality

- Requirements for erosion control measures during construction

- Specifications for materials used in critical areas

City of Charleston building codes

Local building codes also impact material choices:

- Wind load requirements for structures in hurricane-prone areas

- Fire resistance standards for certain types of construction

- Accessibility requirements that may influence decking material selection

Maintenance Considerations for Marine Materials

Proper maintenance is crucial for extending the life of marine structures in Charleston's harsh coastal environment.

Regular inspection and cleaning

Routine maintenance tasks include:

- Washing structures to remove salt buildup

- Inspecting for signs of corrosion or decay

- Reapplying protective coatings as needed

Repair and replacement strategies

When damage occurs, prompt action is necessary:

- Replacing individual boards or sections rather than entire structures

- Reinforcing weakened areas before they fail

- Upgrading to more durable materials during repairs when possible

Innovative Materials on the Horizon

The marine construction industry is constantly evolving, with new materials being developed to meet the challenges of coastal environments.

Emerging technologies in marine construction

Some promising new materials include:

- Self-healing concrete that can repair its cracks

- Nanocomposites with enhanced strength and corrosion resistance

- Biomimetic materials that mimic natural marine structures

Potential applications in Charleston's waterfront projects

These new materials could revolutionize marine construction in the Lowcountry:

- Longer-lasting seawalls that better protect against erosion

- More resilient docks that can withstand stronger storms

- Eco-friendly materials that support marine life growth

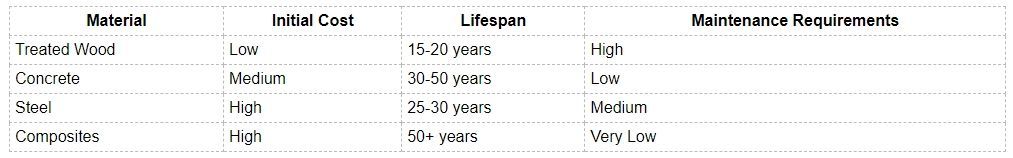

Cost Analysis of Marine Construction Materials

When planning a marine construction project in Charleston, it's important to consider both initial costs and long-term value.

Factors influencing material costs

Several factors can affect the cost of materials:

- Availability of local suppliers

- Transportation costs for materials not produced locally

- Market fluctuations in raw material prices

- The volume of material needed for the project

Long-term value considerations

When evaluating costs, it's crucial to look beyond the initial price tag:

- Higher upfront costs may be offset by longer lifespans

- Lower maintenance requirements can reduce long-term expenses

- Durability in extreme weather events can prevent costly repairs

Material Testing and Quality Control

Ensuring the quality of materials used in marine construction is critical for the longevity and safety of waterfront structures in Charleston.

Laboratory testing of marine materials

Before use, materials undergo rigorous testing:

- Salt spray tests to evaluate corrosion resistance

- Accelerated weathering to simulate long-term exposure

- Strength and flexibility tests to ensure structural integrity

On-site quality control measures

During construction, quality control is ongoing:

- Regular material inspections upon delivery

- Testing of concrete mixtures for proper strength and curing

- Verification of proper treatment and moisture content in wood products

Training and Certification for Marine Construction Professionals

Working with specialized marine construction materials requires specific skills and knowledge.

Importance of proper material handling and installation

Proper training ensures:

- Correct installation techniques for each material type

- Understanding of safety precautions when working with marine chemicals

- Knowledge of local regulations and best practices

Certification programs for marine contractors

Several certification programs are available:

- American Boat and Yacht Council (ABYC) certifications

- Marine Industries Association of South Florida (MIASF) training

- Manufacturer-specific training for proprietary materials and systems

Sourcing Marine Construction Materials in Charleston

Finding the right suppliers for marine construction materials is crucial for project success.

Local suppliers vs. national distributors

Considerations when choosing suppliers:

- Local suppliers may offer quicker delivery and a better understanding of regional needs

- National distributors might have a wider range of specialized products

- Some materials may require ordering from manufacturers outside the Charleston area

Importance of material traceability and documentation

Proper documentation is essential:

- Certificates of conformance for materials

- Mill test reports for steel products

- Treatment certifications for pressure-treated wood

Conclusion

Selecting the right marine construction materials is crucial for the success and longevity of waterfront projects in Charleston. By understanding the properties, benefits, and limitations of various materials, contractors and property owners can make informed decisions that balance performance, cost, and environmental considerations.

As the industry continues to evolve, staying informed about new materials and technologies will be key to building resilient and sustainable marine structures in the Lowcountry. For more information, you can visit our website or contact us.